Kanban

Principle of the KANBAN system

KANBAN (small card, label in Japanese) is a system developed at the Toyota Company which applies the principle of production on demand in production management. Sometimes it is also called a real-time management system. The products manufactured are only those which are actually required by the customer in the quantity and at the time at which the product is required. The KANBAN system precisely defines supplier-customer relations, i.e. circles of workplaces that supply and take both the material and products-in-progress between each other.

When you use system “kanban” you have at disposal whole range of goods which you pay after you have used it. One of the big advantages, besides cost reducing, is that most of logistics does your supplier for you. (It means less paperwork and less work with packaging for you.)

Why to make use of a system “kanban” METALCOM?

Fasteners belongs to so called C items, about which is know that is cheap to buy them, but expensive to implement purchase. It was proved that 80% of the total value of these items is logistical and legislative costs and only 20% is its value. More than 20 years of experience in fasteners wholesale help us to create a complex system which respects market rules and customer needs in different countries.

Types of Metalcom Kanban systems

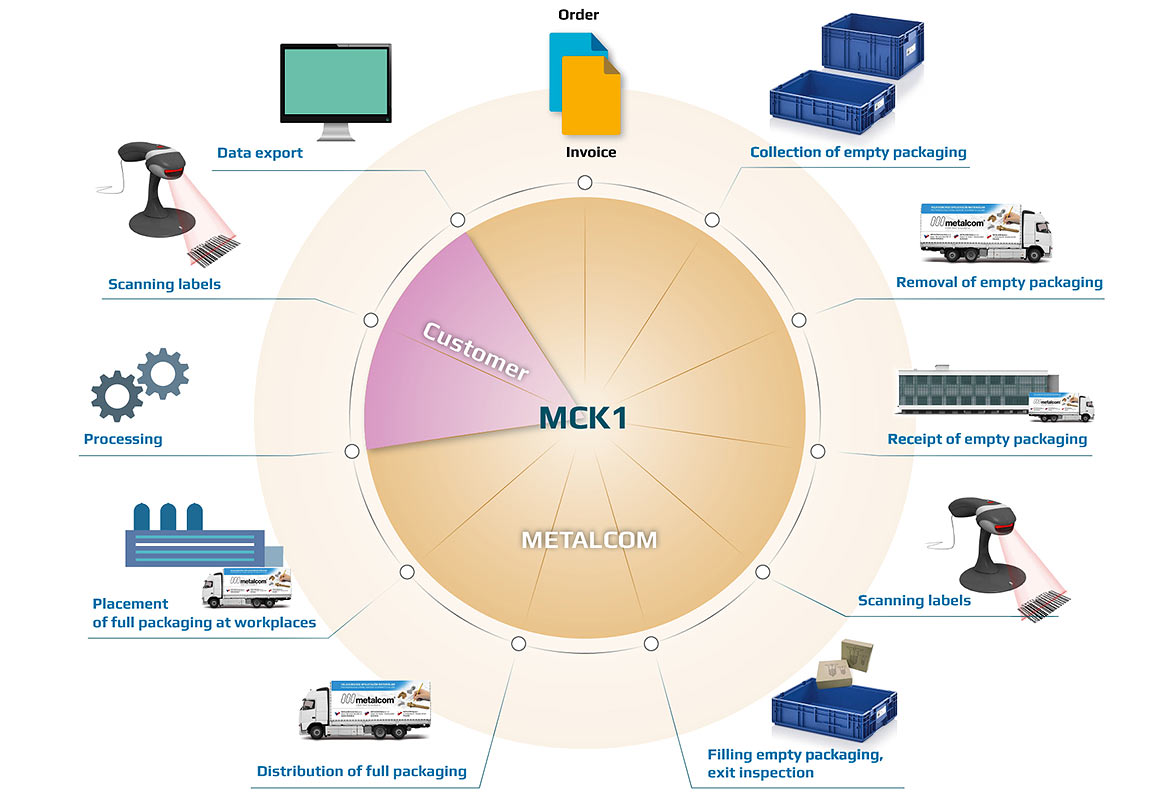

- MCK1 - in the supply of system Kanban METALCOM type MCK1 the kanban card is scanned by the customer.

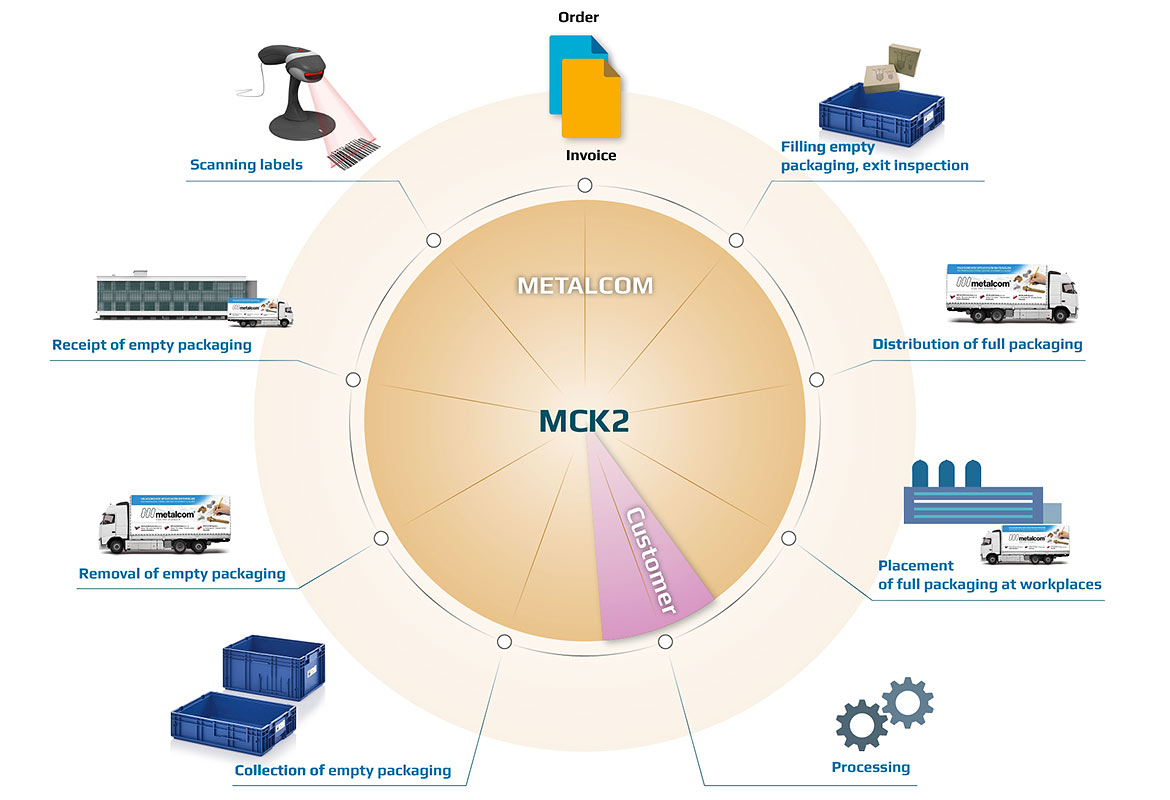

- MCK2 - in the supply of system Kanban METALCOM type MCK2 the kanban card scans the contractor, the customer only consumes goods.

The process of both types is described on schemes as follows:

Prior to start of deliveries

The customer determine the following upon agreement with the supplier:

- Consumption of binding materials in the past period,

- Place of deliveries (warehouse, production, …),

- Quantity of fail-safe supplies (according to storage capacities),

- Frequency of deliveries (according to storage capacities),

- Who ensures racks, types and numbers,

- Type of delivery systems,

- Frequency of invoicing (according to consumption or monthly),

- Number of days to due date from consumption date.

After signing the Contract

The supplier or customer will install racks, programs or scanners on the basis of the agreement and the selected type of Kanban system deliveries. The first transport of the supply will be carried out by the supplier. The minimal number of packages is two to prevent the supply falling to zero status.

We provide for the customer:

- Full responsibility for deliveries of materials without the customer ´s assistance.

- Adapting to their needs.

- Proposal for optimal size of deliveries, supplies, racks and plastic packages.

- Option of establishing more supply points.

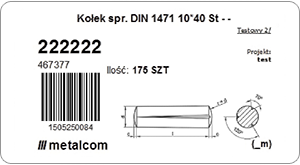

- Bar code system.

- Electronic communication (direct data import of various documents).

- Equipping with service means (racks, containers, scanners, labels).

- Operative changes in case of need.

Means used by our company

Racks

So-called catchment racks are very suitable. They can be easily extended lengthways and their depth can be optimized. They can be equipped with inclined shelves for easy handling.

The principle of catchment racks enables problem-free warehouse release of goods on the basis of the FIFO principle (First In, First Out). This principle can be applied anywhere you want to have perfect tracking of the goods flow. The advanced shape of the frame enables the flexible reconstruction of racks and thanks to large number of accessories enables wide-ranging utilisation. The easily adjustable height of transversal beams enables flexible adaptation of the clear height of individual levels of the goods stored. The catchment rack (KDR) is characterized by simple and quickly adaptable ergonomics according to individual demands of customers.

Vending machines

Packages/containers

The choice of colors, sizes and types is always handled individually with the customer.

Basic types are KLT 3215 (300x200x148 mm) and LF 221 ( e.g. 234x150x122 mm).

Bar code scanners and Printers

Labels

Instructional Video Kanban METALCOM in Poland